Spotlight on Old Road Farm

As our Eat Local Challenge rolls on, we’re shining a bright Member Deals Spotlight on our friends at Old Road Farm! All of their glorious organic produce is 20% off for member-owners from September 21st – 27th! Read on to learn more about these young farmers, the diverse experience they bring to this challenging profession, and their commitment to real organic farming:

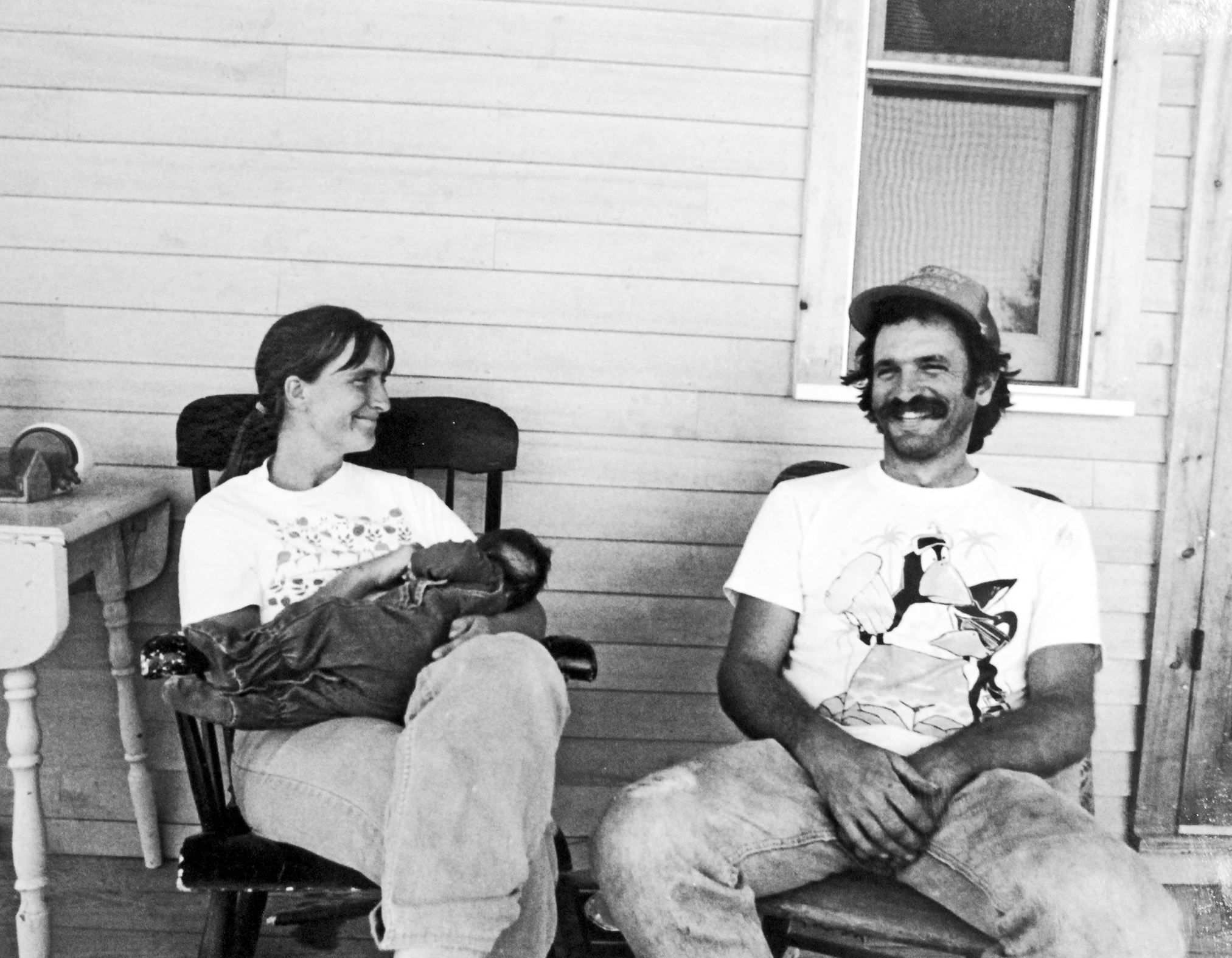

Meet the Farmers

A transplant from New York, Gabby Tuite came to Vermont to attend the University of Vermont where she received a bachelor’s in Community Development and Applied Economics. While studying at UVM, she took an internship at the Shelburne Farms’ Market Garden where she first got her hands dirty and fell in love with farming. After UVM, Gabby worked at River Berry Farm for two seasons. Here she learned how to grow on a larger scale, taking note of the efficiencies required to run a profitable farm. Between growing seasons, Gabby has worked at the City Market Onion River-Coop as a Produce Buyer and Team Leader giving her insight into marketing and merchandising, supervising employees as well as the local food chain from a buyer’s perspective.

Henry Webb grew up with large vegetable gardens and has fond early memories of visiting his father working at the UVM dairy barn. Starting in his teens he spent eight seasons working for Last Resort Farm, a Certified Organic vegetable, berry, and hay farm. He learned to maintain and work on the farm’s equipment and infrastructure as well as organic vegetable farming practices. Henry also spent two years at New Village Farm where he worked with a small herd of Normandie cattle producing raw milk and beef. At New Village, he was given the opportunity to manage and expand the farm’s market garden and gained experience producing for a small CSA, a farm stand, and the Shelburne Farmers Market.

About the Farm

Gabby and Henry shared a dream of owning their own farm and first began their adventure in the Fall of 2015 on a quarter-acre plot in the old field below Henry’s childhood home in Monkton, Vermont, mostly growing vegetables for a few area farmer’s markets. In the Fall of 2019, they were able to secure their dream “forever farm” with the help of the Vermont Land Trust. This gorgeous farm is nestled in the fertile river valley of Granville, Vermont, surrounded by National Forest land.

They specialize in growing fresh, high-quality salad greens and seasonal vegetables for local markets with a deep commitment to the highest standards of ecologically sound, regenerative, and innovative vegetable production. Their produce is Certified Organic by VOF and they are also certified by the Real Organic Project, a grassroots, farmer-led movement created to distinguish soil-grown and pasture-raised products under USDA organic. Gabby and Henry share that they choose to be certified by the Real Organic Project (ROP) because their farming practices are inherently tied to the land and the soil that they farm.

Gabby shares that “In Vermont, we are really fortunate to have the Northeast Organic Farming Association (NOFA) and its certifying body, Vermont Organic Farmers (VOF), who share that commitment, but on a national level, we agree with the ROP that industrialization has in some ways diluted the intent of the organic label. We really don’t like to be critical of anyone’s farming practices, but there are currently things allowed under national standards that we don’t think fit people’s perception of what an organic farm is and we think that consumers have a right to an informed decision about what they are buying. We see our farm, our land, as not just a medium for production but a deeply complex living system that we ultimately bear the responsibility to steward. ROP is an advocate for that view.”

Here at the Co-op, you can find an abundant array of Old Road Farm’s produce, including spinach, chard, salad mix, arugula, collards, sweet peppers, cauliflower, radishes, patty pan squash, broccolini, watermelon, and scallions, each in their respective seasons. If you find yourself traveling Vermont’s iconic Route 100 through Granville, be sure to stop for a visit at their farmstand, where you can find a colorful mix of all the produce grown at their farm, which includes the usual lineup of goodies you can find at the Co-op, along with eggplant, tomatoes, squash, celery, and more!