Forty Years A Co-op

Wow, how time flies! It’s hard to believe that our Co-op is turning the big 4-0 this year. We’ve enjoyed strolling down memory lane in preparation for this big birthday celebration, and we’ve gathered some beautiful stories from Co-op member-owners that have been with us since the very beginning. While many have shared personal anecdotes and fuzzy memories about how the Co-op came to be, and we had a general idea of how it all began, we were still lacking detailed written records to help us understand our beginnings — until we reached out to Charles Adams. He shared this vividly detailed account below, complete with photos. There is an old Abenaki adage which suggests that identity is a function of how well one understands their history. In this way, the gathering of our history has led to a rediscovery of our identity as a Co-op, and for this we are truly grateful.

My Years with the Middlebury and Vermont Co-ops

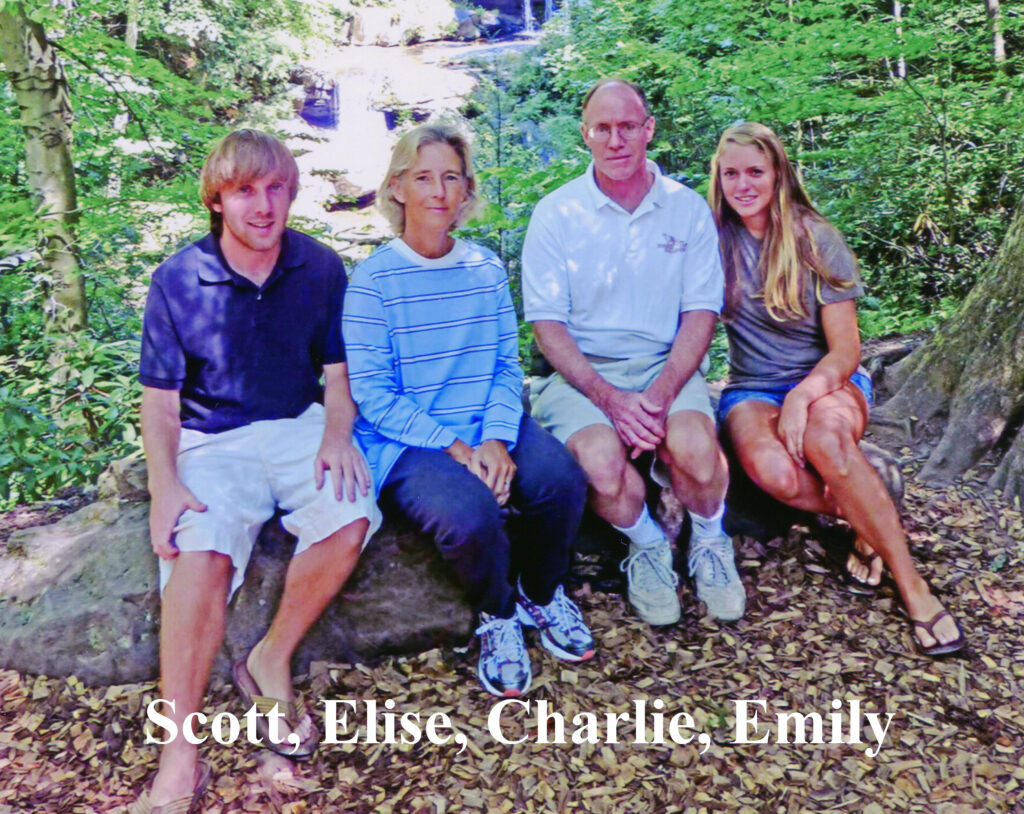

By Charles Adams of Newport, Rhode Island

Like dividing the wheat and other grains from the fields in times of old, each month the Loaves & Fishes Trucking Company would deposit the bulk order of foodstuffs at a rented house on Weybridge Street. On a given Saturday, the neighborhood coordinators from all the outlying towns would converge and with the help of Middlebury Co-op organizers, David Tier & Foxy, each 50# bag of flour, wheat berries, oats, or powdered milk, each wheel of Cabot cheese, each pail of molasses, cooking oil, peanut butter, or honey, and bags of dried fruits, nuts, and seeds would be measured out into smaller containers and driven back to the neighborhoods according to their monthly order sheet.

Dave & Foxy mimeographed and distributed the order sheets which were then distributed to individual families. Once a month the coordinators would collate their neighbor’s orders and return to Dave for collation. Only whole size bags, pails, or cartons of goods could be ordered and efforts were made to minimize leftovers since there was no ability to preserve or store excesses. Middlebury’s orders were then submitted and combined with those of the other 12 Food Co-ops around the state with the Plainfield Co-op as the central leader. Once a month, Carl from the Loaves & Fishes Trucking Co. in the Northeast Kingdom would drive a tractor trailer to the Boston and New York warehouse districts to collect the food haul for Vermont. Then he would drive around to each of the co-ops from Bennington in the south to Derby Ctr. in the north dropping off foodstuffs. Each co-op provided labor to assist with the pickups and deliveries in rotating order. I went on several such trips, including one that suffered a breakdown on the way back from New York with all of Vermont’s food for the month in the back. Those were fun days!

Recognizing the difficulty of dealing with foodstuffs on the front porch and the growing popularity of the Co-op, Dave rented an improved barn on Rt. 7 south of New Haven for the monthly distributions. This greatly expanded the space available for subdividing the food, made organization of the process possible, and kept everything out of the rain and wind. About springtime 1975, Dave & Foxy were ready to hand off their management duties and my girlfriend, Barbara Charbonnet, and I accepted the responsibility.

All the flours and cornmeal distributed by the Vermont Co-ops was milled on a Meadows 30 inch stone mill originally purchased from Erewhon, a large natural foods distributor near Boston. The miller was Henry Tewksbury and the mill was located in a back room at the Plainfield Co-op. The mill was known affectionately as ‘Audrey’ as it was the sister mill to ‘Jane’ which was also owned by Erewhon.

There was growing dissatisfaction in Middlebury with the co-op location out of town and with the ‘once-a-month’ system over time and about mid-summer 1977, the old REA baggage building adjacent to the Middlebury train station (then a NAPA auto parts) was rented from Joe Bok. Volunteer labor from members cleaned the building, painted walls, repaired floors, and built shelves. As the sparsely paid coordinator, I lived in the ‘storefront’ for a winter with a wood-burning stove and my Russian wolfhound, Sonja.

With the help of Walt Miller, who taught me double entry bookkeeping and exercised some oversight of the growing bank balance of the co-op, we accumulated enough reserve to begin buying ‘extra’ food for a storefront operation several days a week, gradually increasing the extent of the items offered for sale.The pre-order operation continued and had lower pricing than the storefront. It was always the pre-order folks who were the lifeblood and base of volunteers that kept the co-op alive and performed its tasks.

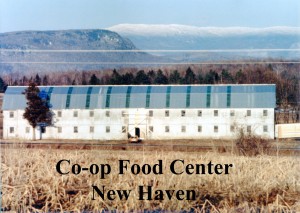

About year-end 1977, the Vermont Co-ops decided that business had grown to the point that they needed to establish a warehouse for the temporary storage, trans-shipment, and logical loading of the trucks for deliveries. As well, the flour mill would be re-located to this, more central and accessible location from Plainfield. However, the miller wasn’t going to re-locate, and I volunteered to become the new miller. A large barn on South St. in New Haven which used to be a chicken farm was rented, steam cleaned, and painted. A loading bay was built, office area enclosed, 3-phase power service installed, the mill moved and set up, staff hired, and operations begun. Ellen Temple was the warehouse manager and I was the miller.

About twice a year, the mill was disassembled and the turning millstone was removed so that the lands and grooves could be leveled and sharpened. The milling process slowly dulled the stones to the point that more and more pressure had to be used forcing the stones together to accomplish the degree of fineness required in the flour. This pressure would produce heat which was not desirable as it would destroy the nutrients in the whole wheat flour and could produce sticky flours which would jam the mill and flour transport. The dressing of the stones was done with a carbide-tipped chisel and air hammer – not a pleasant job!

My guide in setting up the mill and laying out expansion plans was Oliver Evans (1755-1819), Young Millwright & Millers Guide, re-printed in 1850. The mechanics of receiving, storing, moving, cleaning, milling, and bagging grains was unchanged from his time except by the luxurious addition of electric motors. Essentially the vertical orientation of machinery was identical to the early mills.The warehouse never got a freight elevator so every 50 and 100 pound bag of grain and flour had to be shoulder-carried up and down the stairs. I might add that these stairs were built by Paul Ralston , then the volunteer laborer provided by Old Nash Farm on a work weekend while we were getting started.

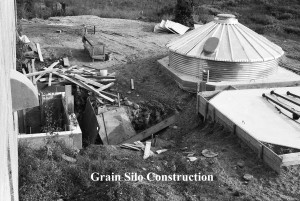

The mill operation expanded with the purchase of Vermont-grown wheat in bulk, the construction of a grain storage silo, grain elevator, and purchase of a commercial seed cleaner (from French’s mustard). The Vermont Federation of Co-ops eventually discussed the possibility of marketing its flour through commercial grocery stores such as Grand Union in smaller quantities (5 pound bags). However, the regional managers collectively decided that this was a step too far outside the co-op spirit of volunteer labor holding the enterprise together. I disagreed with that decision, feeling that the economics of flour milling are volume-driven. The profit per pound is extremely low and only volume sales can hope to carry the capital expenditures necessitated by the equipment required.

By the summer of 1979, my work with the Co-ops was done. Stephen Pilcher agreed to take over my flour milling duties. I had decided to go to UVM and proceeded to get a degree in Electrical Engineering. I look back with great pride in the work of those years, in the friendships formed, mostly under pretty adverse conditions, the results achieved, and the sense of community present at every level from the neighborhood coordinators, to the regional co-ops, and even the New England Co-ops (NEPCOOP, New England People’s Co-op). It was a time of idealism, hope, and promise for the future.

Seeing that the Co-op has endured and grown makes me immensely proud and happy to have been a part of its origins.

![IMG_3627[1]](https://middlebury.coop/wp-content/uploads/2016/03/IMG_36271-300x225.jpg)

![IMG_3630[1]](https://middlebury.coop/wp-content/uploads/2016/03/IMG_36301-300x225.jpg)